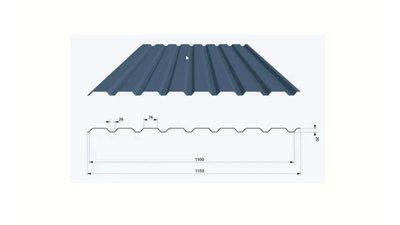

Descripción

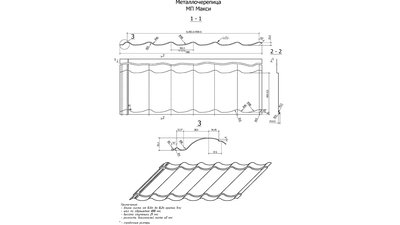

Tile pressing machinery

Equipment installation overall size: 8000mm × 1500mm × 1800mm

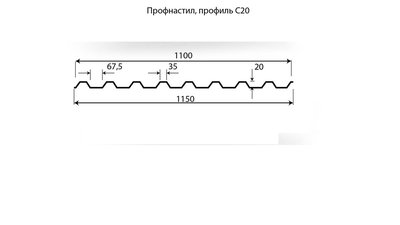

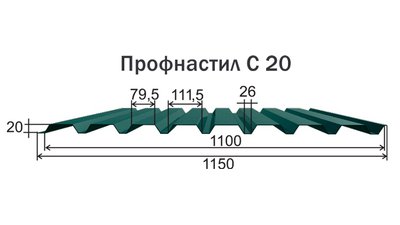

Feed width: 1250mm. The feeding platform adopts a manual adjustment for precise feeding

Feed plate thickness: 0.4~1.0mm galvanized sheet, color steel plate

Forming shaft diameter: 80mm diameter (solid spindle)

Forming process: 15 rows+15 rows forming

Roller material: Large roller 45 # precision turning, deep quenching, hard chromium plating, mirror plating (delayed for 1 hour), equipment weight approximately 8.5-9 tons (subject to actual equipment)

Cutting method: reinforced hydraulic automatic floor cutting system (without material connection and labor saving)

Hydraulic station power: 11kw high-speed hydraulic air-cooled belt heat dissipation pump station

Drive mode: 7.5kw servo motor with fast speed and precise board output

Main bearing: National standard quenched bearing steel bearing

Equipment rack: thickened 400 # national standard H steel welding plate: 18mm

Transmission method: 1.2 inch brand national standard quenching chain transmission

Cutting blade material: Gr12 molybdenum vanadium blade, thick steel plate, welded, profiled, shear guide pillars, all thickened, reinforced, precision turned, quenched, shear oil cylinder, high-speed hydraulic oil cylinder

Fixing method: Grade 8.8 high-strength screw, thickened wall tie rod, thickened square steel hanging wire plate

Servo board output speed: single board 16-25 meters/minute, glazed tile 4-6 meters/minute

Electronic control system: The entire machine adopts the most advanced electronic control system, with a 10 inch touch screen and a split electronic box of electronic components from brands such as Delixi Zhengtai. It can input 50 order sizes and has a broken board reminder function.

Random accessories: one pair of upper and lower cutting knives, one solenoid valve, two counter wheels, four solenoid valve light caps, four travel switches, four buttons, and ten electronic fuses